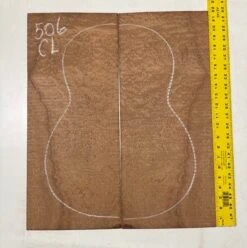

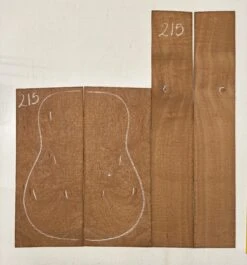

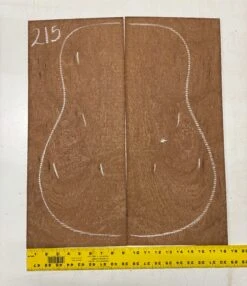

Premium Leopardwood 4/4 Lumber

$123.90 Original price was: $123.90.$86.73Current price is: $86.73.

- There are quality problems, free return and exchange

- Unbeatable Quality, Unbeatable Value

- 100% High Quality Guarantee

- 100% Quality Promise

Leopardwood

Leopardwood gets its name from the beautiful flecks that cover its surface. Leopardwood features a light to medium brown base color with dark brown or black spots or patches scattered across the surface and is simply gorgeous. It’s primarily quarter sawn, which creates stunning leopard-spot patterns. Leopardwood has a medium to coarse texture with a straight to interlocked grain. It has a fine and uniform texture, which contributes to its smooth finish when properly sanded and finished. The wood often exhibits a natural luster, adding to its visual appeal. It is often used in furniture, flooring, and other decorative items, cabinetry and making cutting boards and cheese cutting boards .It has good resistance to warping, twisting, and checking. It is also a dense and hard wood, making it durable and suitable for various applications. Common uses are furniture ,musical instruments, turning and carving.

Scientific Names :Roupala montana (syn. R. brasiliense)

Distribution: Central and South America

Janka Hardness:Central and South America

| LENGTH | 75″ to 85″ (Inches) |

|---|---|

| WIDTH | 5″ to 10″ (Inches) |

| THICKNESS | Nominal Thickness 4/4 (The planning/smoothing process removes some thickness) See Explanations |

| KILN-DRIED? | Yes |

| MOISTER CONTENT | 7% to 9% |

| GRADE | Select & Better |

How To Order Lumber

What is Nominal & Actual Thickness?

About Lumber Sizes

Width: 5″ to 10″

The price shown is for a random selection of widths within this range. If you need custom widths, please contact us. (We also provide straight edge rip for free)

Length: 75″ to 85″

This is the range of lengths that we might have in stock. The length you receive depends on how much you order.

Thickness: 1″

Also known as 4/4,

If you need a planned and smooth surface, we provide it at no cost. (Note: the planning process removes some thickness.)

See Surface Finishing Details

How To Order Lumber

What Is Surface Finishing/Planing?

Rough Sawn- The edges are rough cut and both surfaces will be unplanned. SLR1E (straight line ripped one edge )- one edge is ripped straight. SLR2E (straight line ripped two edges)- two edges is ripped straight. S2S – The board has been run through a planer producing two flat faces, but the edges are left rough. S3S – The board has been surfaced S2S first, then one edge is ripped straight (also known as SLR1E or straight line ripped one edge). S4S – The board has surfaced on both faces (S2S) and received a rip on both edges, resulting in a board with two flat and parallel faces and two flat and parallel edges. This is the stuff you usually find for sale in the hardwood section of big box stores like Home Depot and Lowes.

Note: Planing will reduce the total board feet you receive slightly. Moreover, the actual thickness may vary slightly.

Are these rough cuts?

What is nominal thickness and actual thickness?

| Nominal Thickness | Actual Thickness (S1S) | Actual Thickness (S2S) |

|---|---|---|

| 4/4 (1″) inch | 7/8 inch | 13/16 inch |

| 6/4 (1-1/2″) inch | 1-3/8 inch | 1-5/16 inch |

| 8/4 (2″) inch | 1-13/16 inch | 1-3/4 inch |

| 12/4 (3″) inch | 2-13/16 inch | 2-3/4 inch |

| 16/4 (4″) inch | 3-13/16 inch | 3-3/4 inch |

Do you do custom cut?

Please email at [email protected]

Or contact us Here

I’m placing a large order. Do you ship freight?

| Board Feet | 5 Board Feet, 10 Board Feet, 20 Board Feet |

|---|---|

| Free Surface Finishing | Rough Edges, (SLR1E) Straight-Line Ripped One Edge, (SLR2E) Straight-Line Ripped Two Edges, (S2S) Surfaced Two Sides, (S3S) Surfaced On Three Sides, (S4S) Surfaced On 4 Sides |

Be the first to review “Premium Leopardwood 4/4 Lumber” Cancel reply

Related products

Madagascar Rosewood

Madagascar Rosewood Classical Guitar Back And Side Seconds Set #522

Quilted Sapele

Quilted Sapele

Madagascar Rosewood

Madagascar Rosewood Classical Guitar Back And Side Seconds Set #517

Madagascar Rosewood

Madagascar Rosewood Dreadnought Guitar Back And Side Seconds Set #5077

Reviews

There are no reviews yet.